When Two Worlds Come Together

When two worlds come together, a new universe opens up. That’s exactly what happens in Bekenstein’s research group, where a synergistic combination of two scientific fields is achieved: On the one hand, the traditional and the well-developed field of Material Science. On the other hand, the innovative and emerging field of Data Science.

The newly established research lab of Prof. Yehonadav Bekenstein at Technion is investigating materials that are called Perovskites. These are synthetically grown compounds that have a unique crystalloid structure and a general chemical formula of ABX3. Technology based of these materials promise breakthrough properties, for the field of energy and opto-electronic devices, such as light emitting diodes and solar cells. In order to engineer the optimal qualities of these materials for their future implementation into markets, it is required to conduct a large number of experiments and compare the results. However, this Edisonian experimental approach of trial and error is slow, inefficient and costly. Here is where Data Science comes into the picture. Machine learning algorithms, coupled with powerful data processing, can predict the results based on existing data, and deal with difficulties that a human researcher is not capable to overcome.

One advantage of the machine over human is in its ability to comprehend multi-dimensional data. While the human understanding is limited to a visual representation of 2 or 3 dimensions in a figure, the machine learning algorithms can find patterns in multi-dimensional space. This approach is very relevant to the research of perovskites, since their structure, and therefore their optical and electrical properties, are affected by a large variety of features. Variations of these features, such as the growth temperature, reagents concentration, and method of synthesis, can lead to very different outcomes. One example we currently study is the dimensions and shape (e.g. cubic, rod-shape, or a layered structure) of perovskite nanocrystals. Using machine learning, we can predict the optimal features for the desired structure and behavior of such nanomaterials.

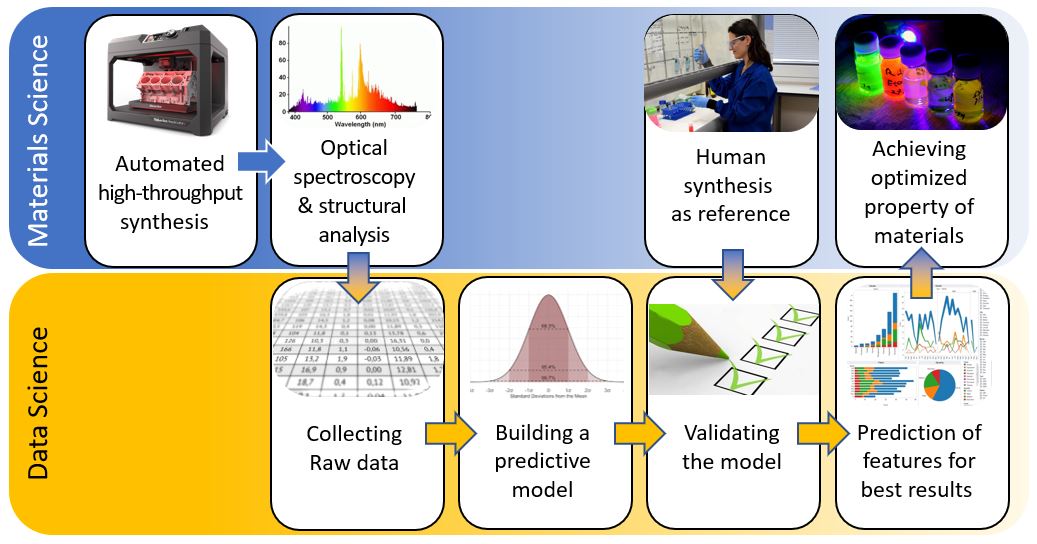

Our vision for a future material-science lab is to combine automated high-throughput synthetic processes with an inference machine learning based predictive model. The reason for this is that the performance of the machine learning algorithms depends on the data volume and quality. We envision a large number of experiments that could be done simultaneously with little human effort, providing big experimental data. This makes us one step closer to the era of Big Data in the world of Material Science.

Theorized workflow of a future data-driven material discovery and optimization process:

High throughput parallel synthesis for materials discovery and engineering

Next generation materials demand silicon era engineering. In order to meet the challenge, we develop methods to run multiple experiments simultaneously in combination with machine learning. On the synthetic side we implement a nonstandard approach using modular high-resolution 3D printer for this task.

For example to develop optimized synthetic protocols for brightly emitting perovskite nanocrystals. Moreover, the advantages of a 3D printer over standard pipetting robots ,is the preparation of complex samples with a high control of their shape, size and concentration which is essential for down the line optical characterization and devices.